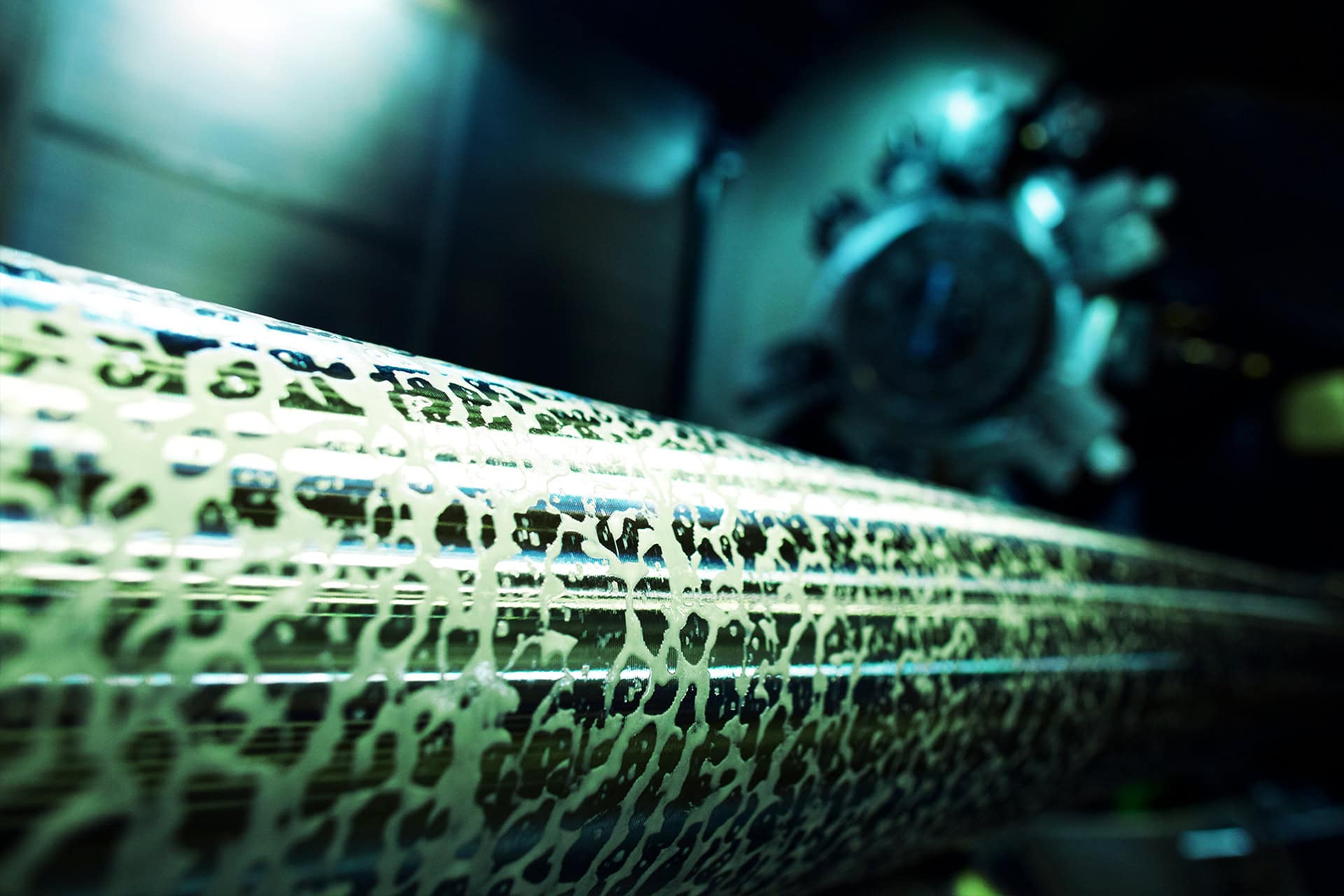

You can count on Promac Sawmill’s longstanding reputation for quality, durability and top-of-the-line service in wear parts.

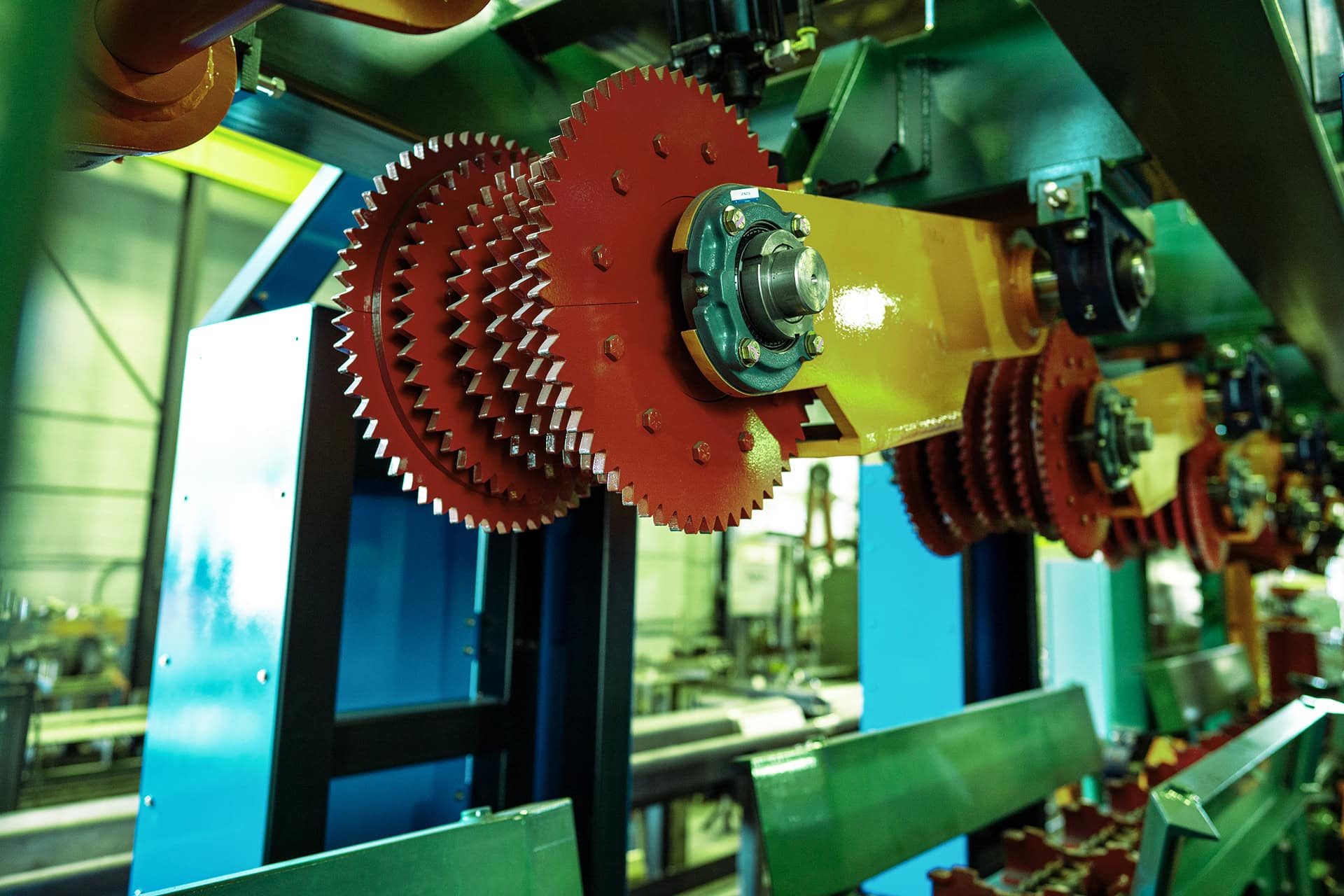

Rare combination of high capacity and flexibility

Promac happily fills your specialized parts requests

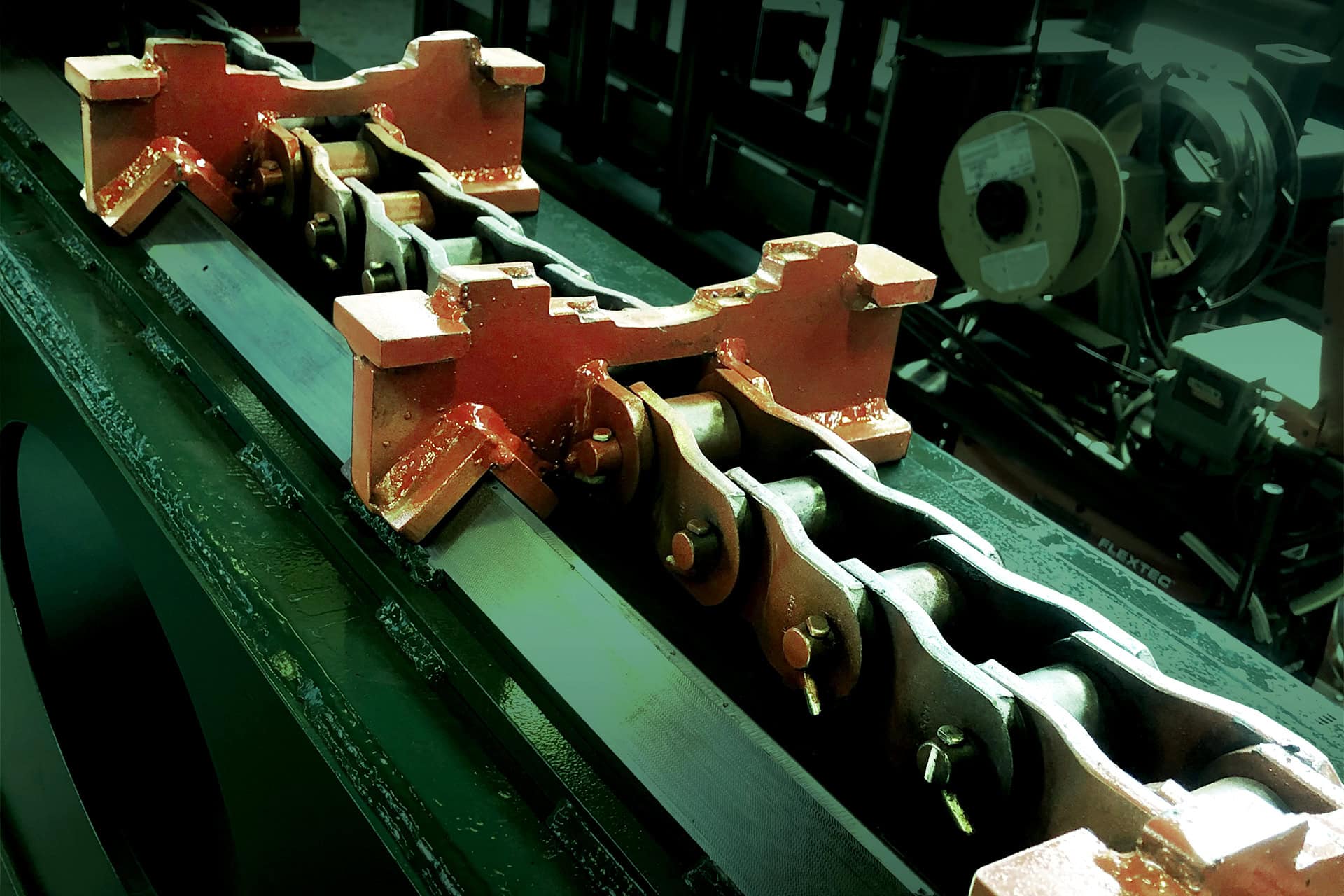

Promac Sawmill’s adherence to serving the customer first means you decide your order, not us. You might not expect a top supplier of sawmill parts across North America to work with sawmill’s closely on personalized/specialized upgrades, downgrades, modernizations, alterations, conversion packages, AND for quantities both large and small. Not only will Promac Sawmill fulfill sawmill’s unique requests, they will spend quality time to ensure success, using their expertise and engagement in the industry, and back-and-forth discussions, to provide ongoing consultation over the performance of parts and mills as a whole, assuring operations remain as optimal as possible.

The history speaks for itself

Serving sawmill wear parts for 35+ years

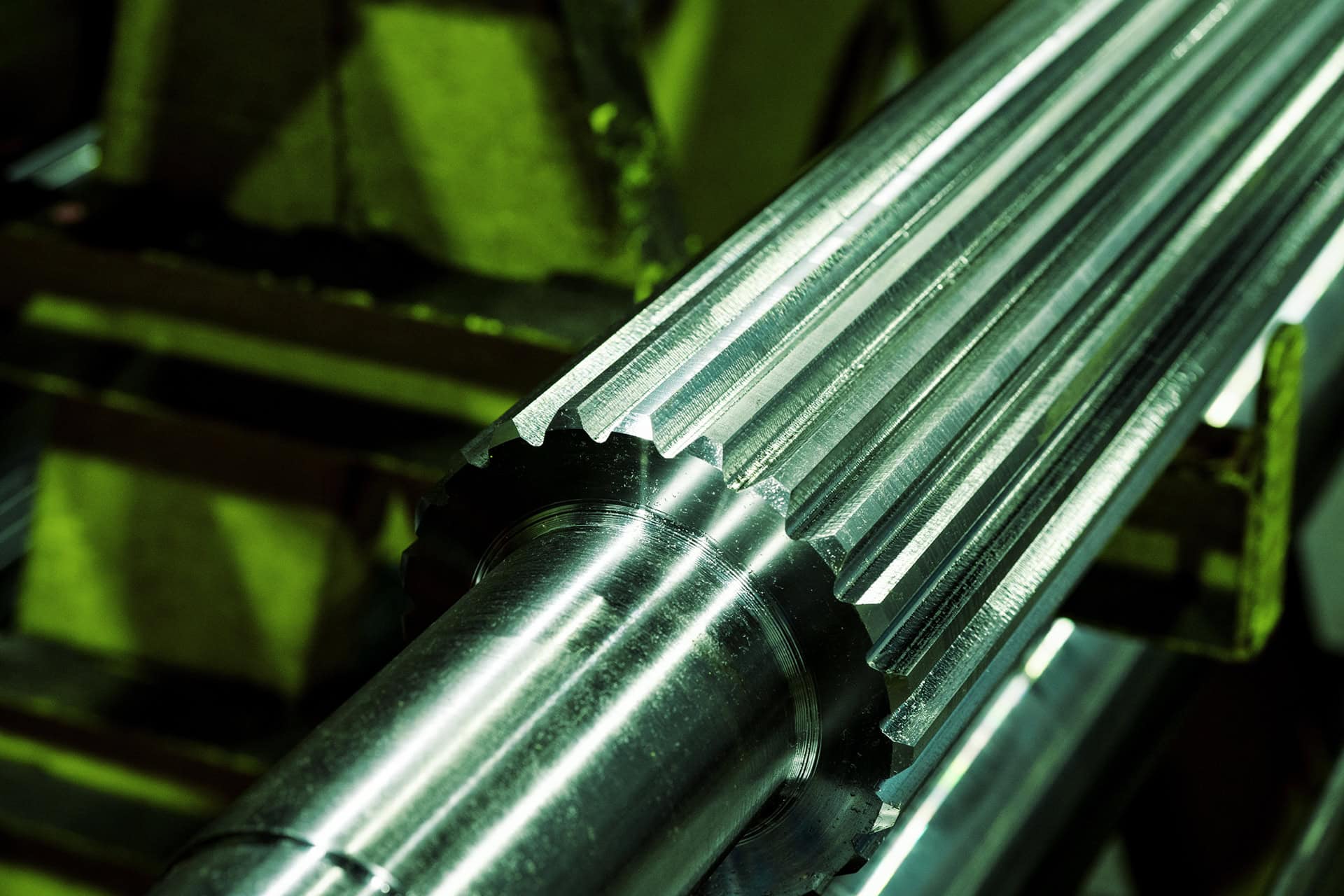

Starting with arbors and saw guides 35+ years ago, and shortly after expanding to provide service and supply of many more crucial, standardized and high wearing sawmill parts, Promac Sawmill has now gained 20+ years experience on the majority of parts in their catalog. With this much time and experience to help form current decisions throughout manufacturing processes, Promac Sawmill’s parts catalog is backed by proven minds and proven performance.