YEARS OF SAW

GUIDE EXPERIENCE

GUIDE EXPERIENCE

COMPANY TOTAL (ESTABLISHED IN 1978)

36

REPEAT SAW

GUIDE CUSTOMERS

GUIDE CUSTOMERS

OVER PAST 10 YEARS (2015 - 2025)

130

SAW GUIDE

UNITS SOLD

UNITS SOLD

OVER PAST 10 YEARS (2015 - 2025)

22,814

Promac saw guides have led saw blades across North America wood processing industries for 35+ years.

Eg. Steel

Eg. Aluminum

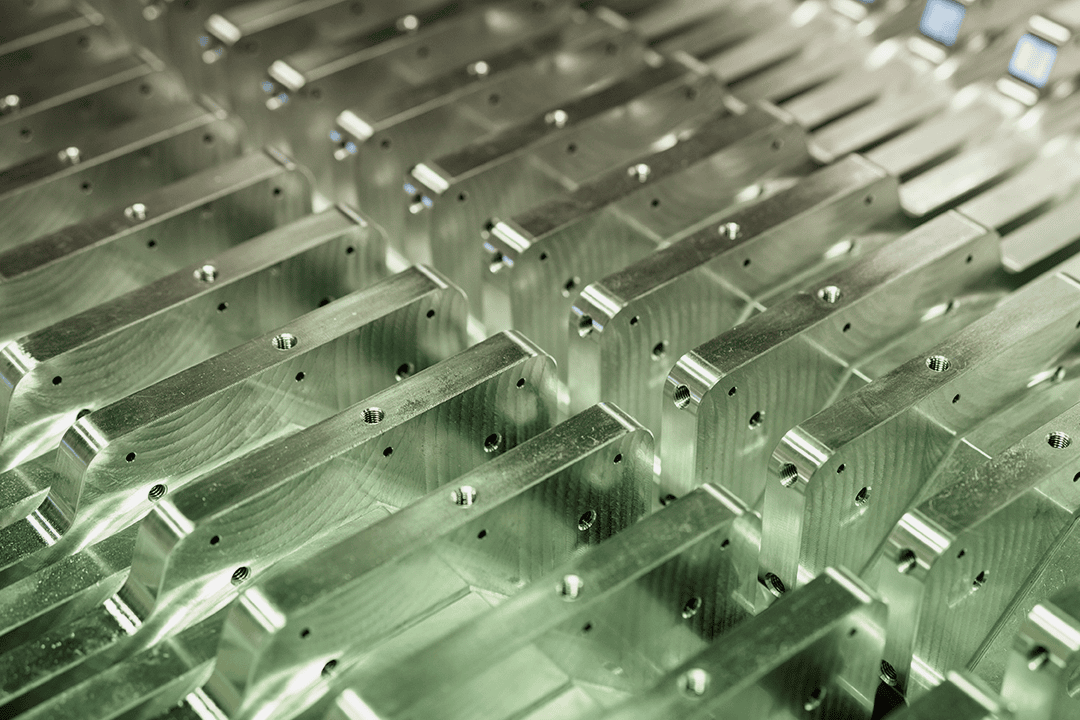

Saw Guide Features:

Modified jet holes, lube pockets and channels to improve cooling

Custom guides quoted fast with 14-day turnaround times

Precision surface ground finish for steel guides

Increased babbitt surface area to improve saw support

Able to resize existing guide stock for target changes

Type III Engineering hard coat for aluminum guides

Speed Up Quote Requests With Our Updated Print-N-Fill Form

Package in babbitt pad upgrades with a new babbitt jig!

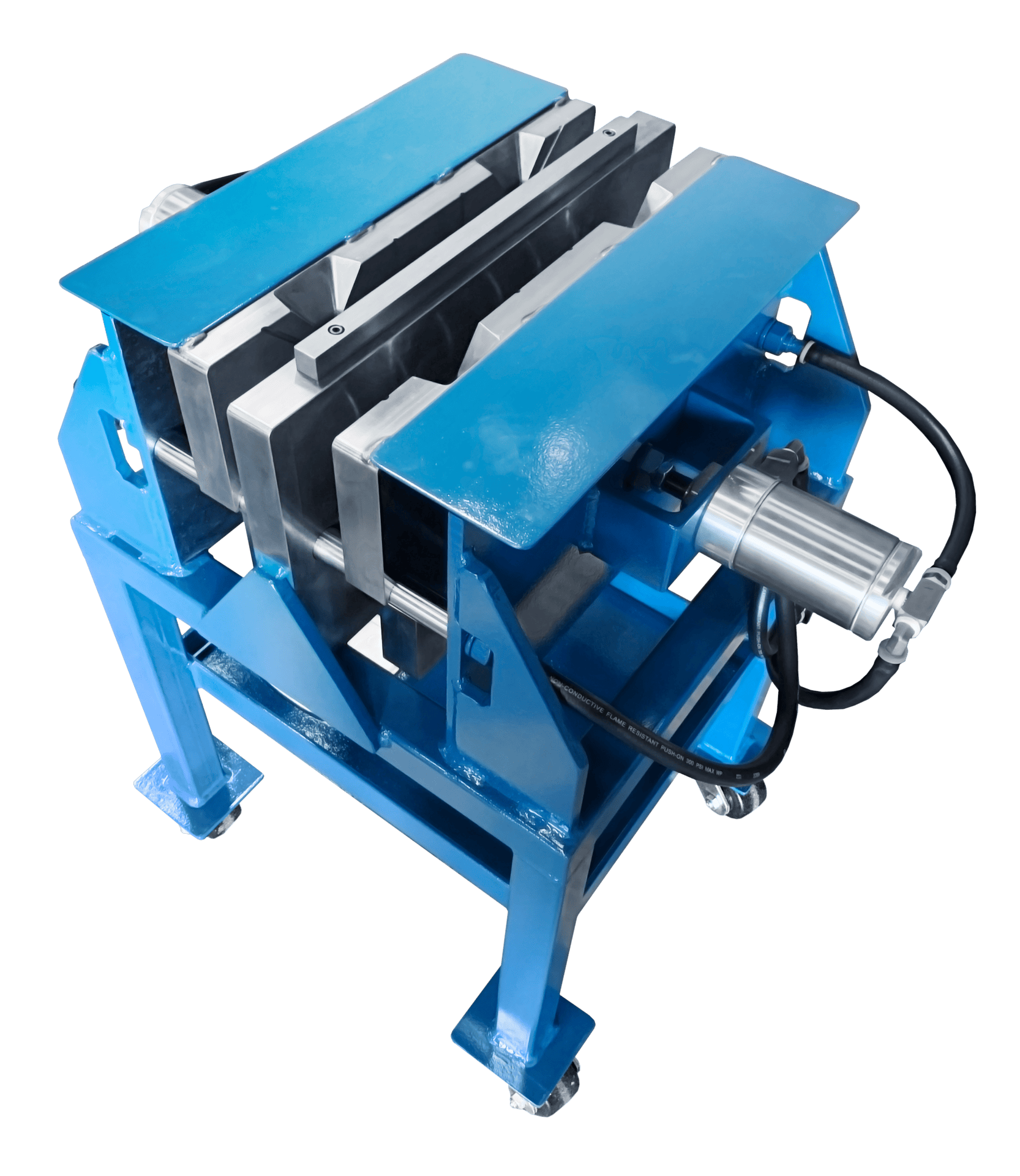

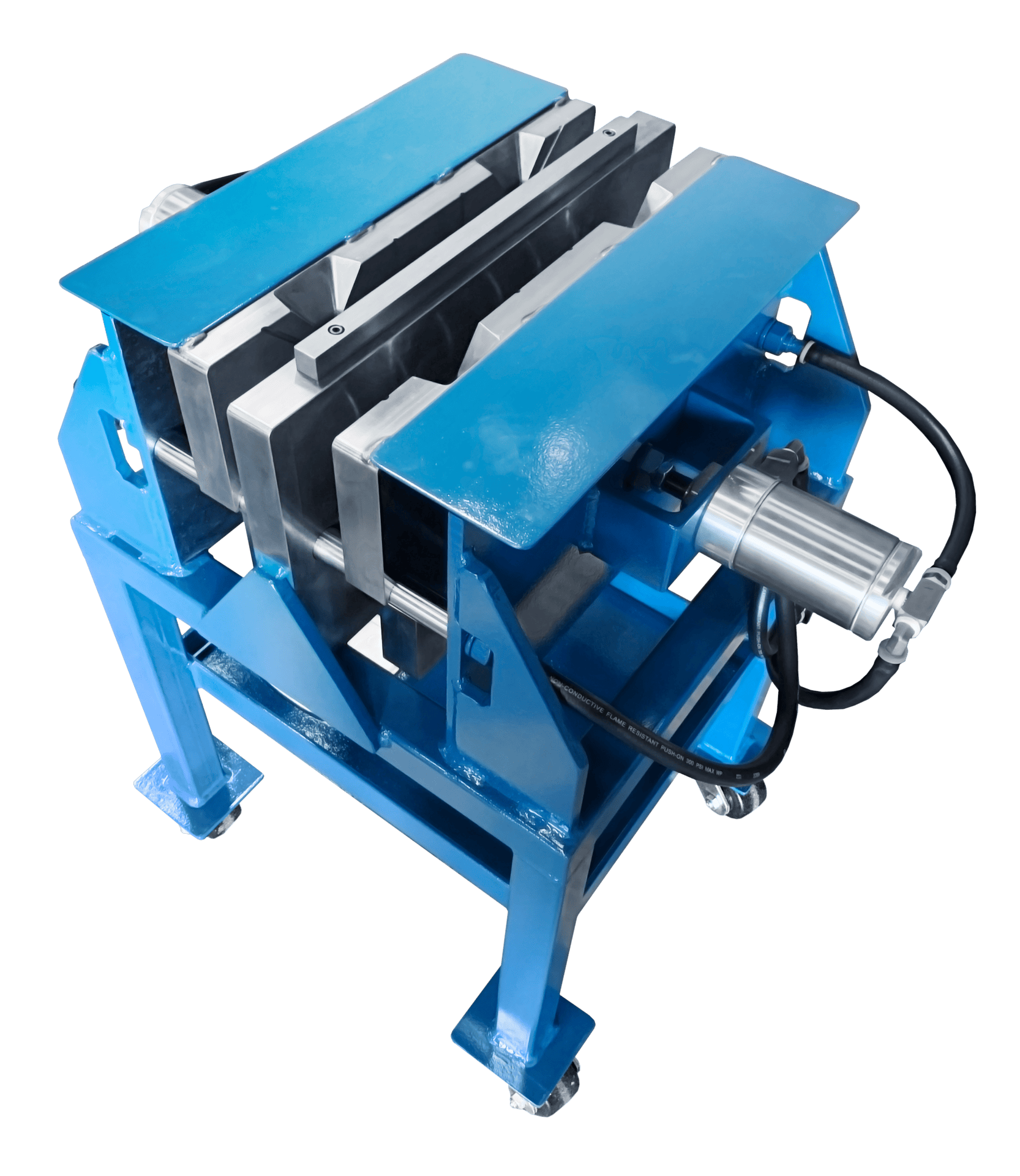

Babbitt Jigs

Convert to bolt-on babbitt pads

Simple, robust, economical

Pneumatically activated release