YEARS OF SLEEVED

ARBOR EXPERIENCE

ARBOR EXPERIENCE

COMPANY TOTAL (ESTABLISHED IN 1978)

38

REPEAT SLEEVED

ARBOR CUSTOMERS

ARBOR CUSTOMERS

OVER PAST 10 YEARS (2015 - 2025)

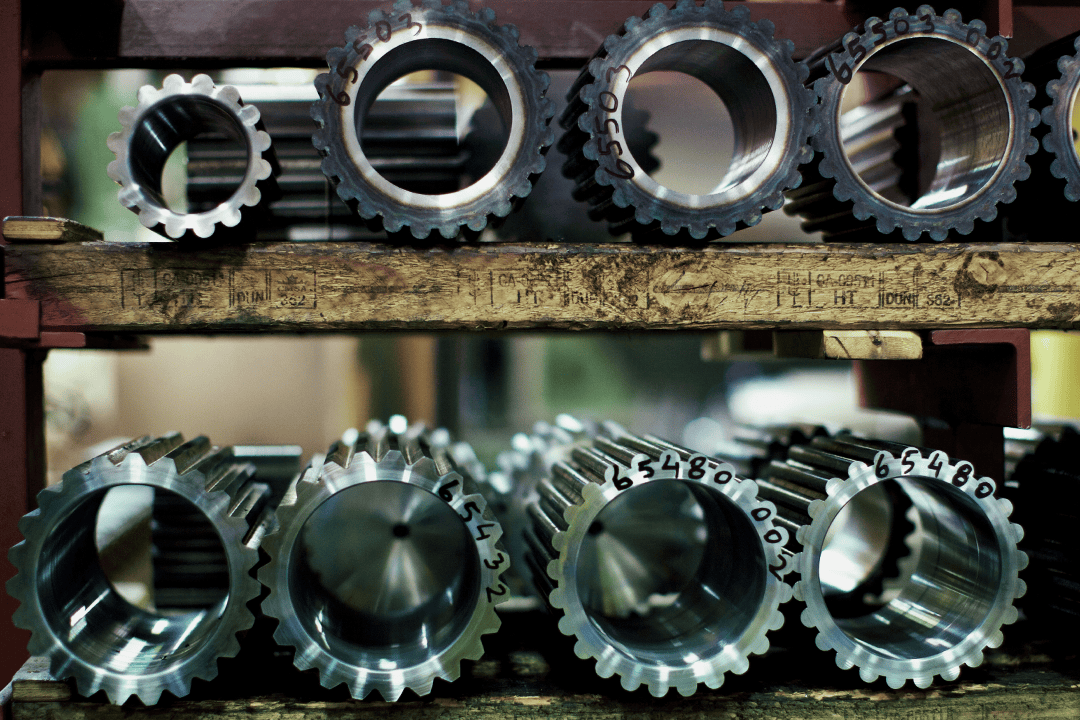

150

ARBOR SLEEVE

UNITS SOLD

UNITS SOLD

OVER PAST 10 YEARS (2015 - 2025)

7,980

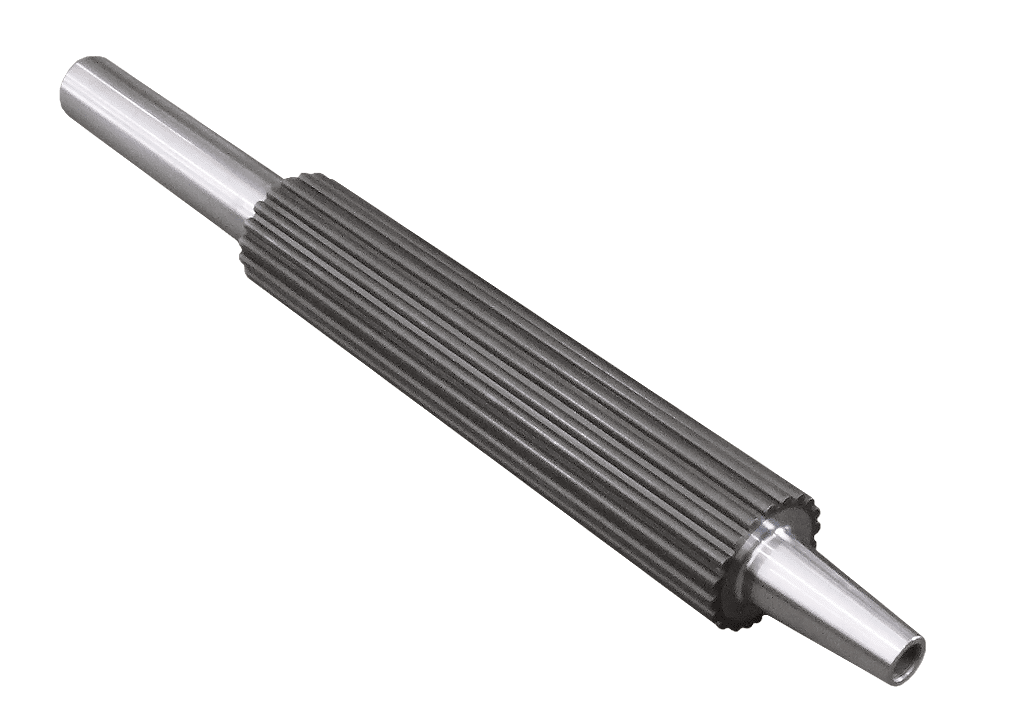

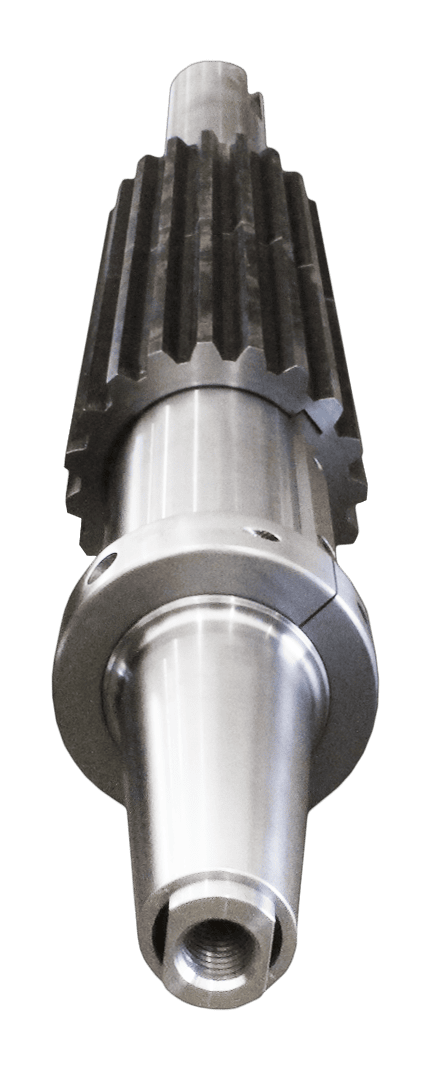

Promac sleeved splined arbors offer advantages in maintenance procedures long term costs – backed by 35+ years experience in sawmill arbors.

Sleeved Splined Arbor Features:

Spline T.I.R. is 0.004”, 0.001” across journals

Shaft design and Q.C. remains in-house

Mandrel shafts machined from 4140 HTSR

Accurate keyway alignment enables shifting applications

Chromed and ground to prevent corrosion and fusing

Optimized sleeve bore tolerances results in minimal runout

Swap and flip sleeve allows 4 x longer maintenance intervals

Features heavy duty sleeve retaining nut

Ask about converting your solids arbor to sleeved!