We’re leaders in sawmill technology.

We help sawmills enhance performance and improve the ease of maintenance on primary breakdown equipment. We provide the most comprehensive range of sawmill solutions to customers across the world. Our solutions dramatically improve accuracy and feed time and reduce down time. We specialize in log handling and canter line machinery, and have experience in every aspect of the sawmill environment. Over the years we have developed ground-breaking innovations in in-feed hold downs; compact, high speed log turners; the toughest log singulators and more. All of our solutions are designed to ensure ease of maintenance, product quality and efficiency.

In-feed section

FEATURES

- Complete, extended and double length in-feeds with ease of maintenance at the forefront

- Double length in-feed chain – any flight, any profile

- Proprietary in-feed hold down roll with reversible/ replacement teeth

- Hold down roll conversions to pneumatic tires (ATV) with “the best hub in town”

- Pneumatic tire holds down rolls for high-speed small log canters (logs from 4” dia. to 18” dia.)

- Quad spiked rolls and conversations

GET A QUOTE

Dave Carlson

Sawmill Machinery Manager

250-710-1691

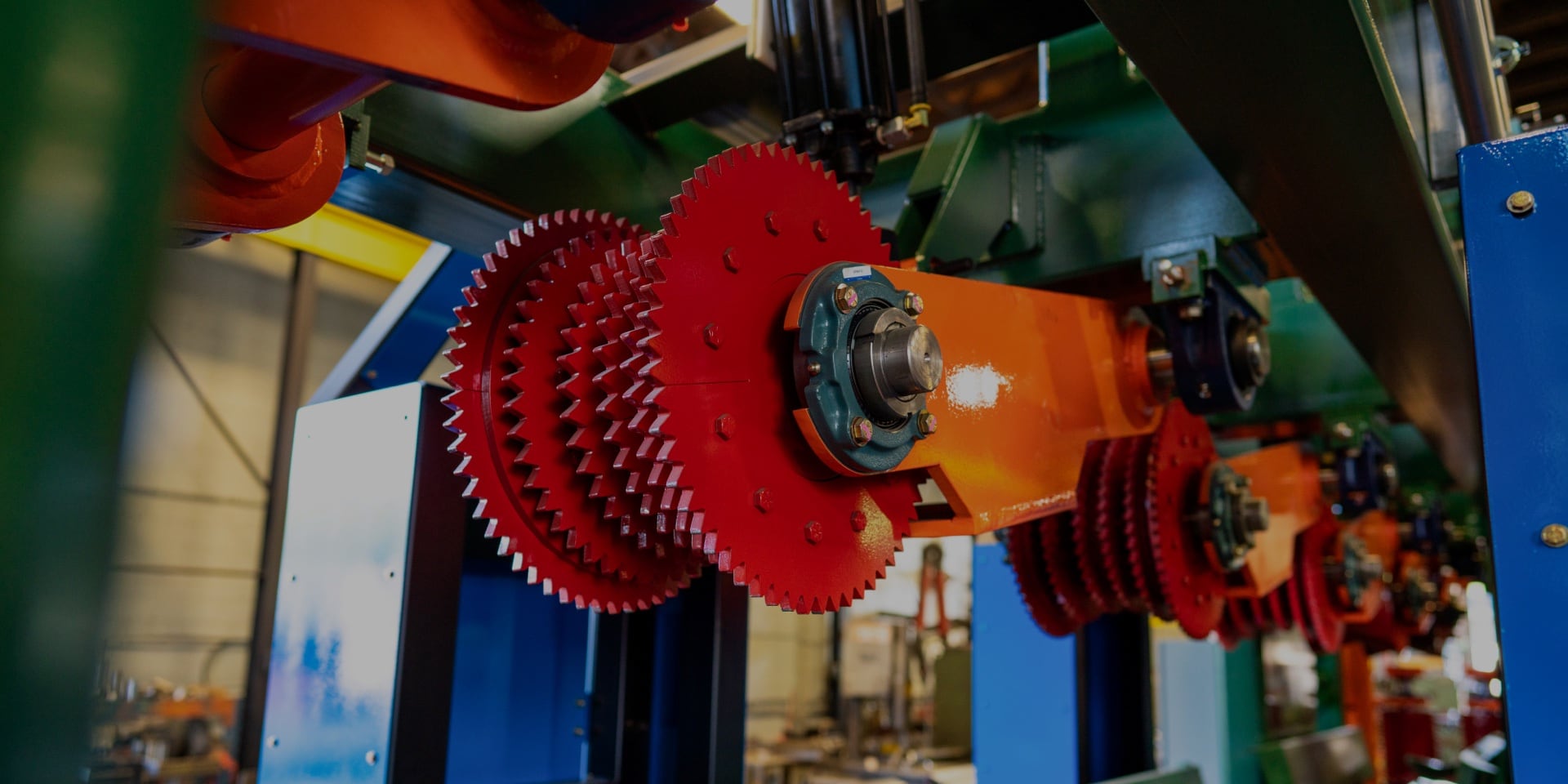

Log turners

FEATURES

- Dual roll and quad roll log turners

- Spiked roll drive conversion with universal splined drive shafts

- Spiked rolls with replaceable threaded spikes

- Rockwell sports model log turner

- Add a compact high-speed log turner to your existing log turner for enhanced for “corrective scanning” and turning

Chipping section

FEATURES

- Complete chipping section frames

- Precision machined and professionally balanced segments for CNS knife, flat knife, key knife and other knives

- Feedrolls – Knurled and chromed. Coleman rolls with wedge clamps and easily replaceable inserts

- Guide bars – All profiles, all heavy chrome

- Arborsand arbors nuts with ‘Loq-pin’ option

- Chip chute rebuild kits for top head and side head chip chutes

GET A QUOTE

Dave Carlson

Sawmill Machinery Manager

250-710-1691

Saw section

FEATURES

- The latest in vertical double arbor edger (D.A.E.)designs

- Saw arbors, splined sleeves, splined arbors

- Saw guides – Aluminum and/or steel. Any shape, any size, for any edger.

- Saw guide conversionsto edgers with collared saws, as well as existing guided saw edgers

- Bed rolls and vertical feedrolls

- Guide bars

- Splined drive shaft conversions for V.D.A.E. feedrolls

GET A QUOTE

Dave Carlson

Sawmill Machinery Manager

250-710-1691

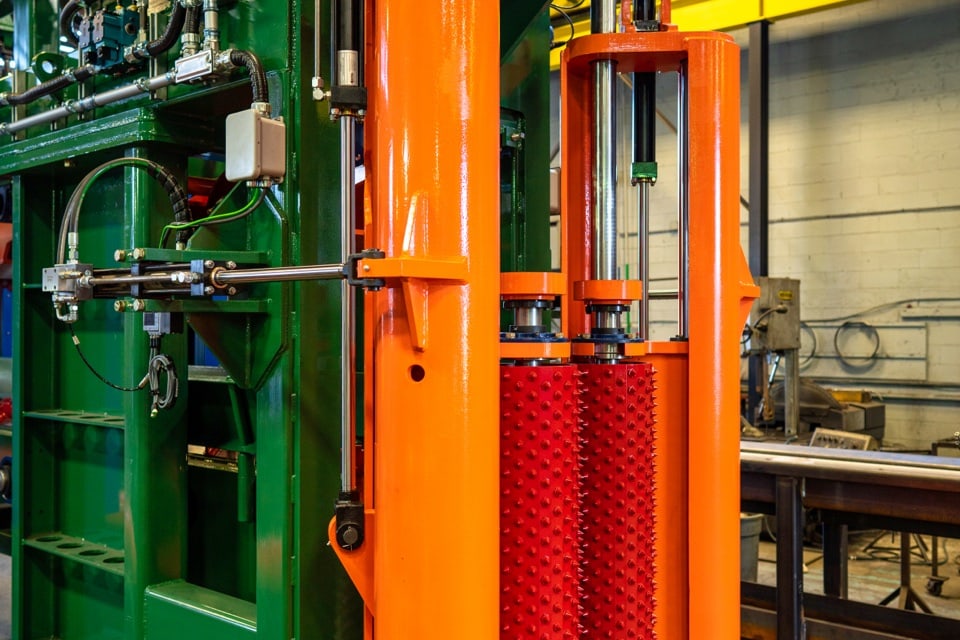

Log singulator

FEATURES

- Each stage of the singulator is powered by a direct-coupled electric drive with an independent flux vector controller

- Guaranteed singulation with no ‘empty steps’

- No heavy moving masses

- Self-cleaning, balanced design

- Virtually maintenance free

- Any Length, any width, any height, any log size

- Feeds 30 logs a minute at random length (20 feet max) and up to 50 logs a minute at stud length (10 feet max.)

- Feeds up to 20 logs per minute with stem length 60 feet max

Upgrade / Conversion packages

FEATURES

- We work with sawmills to design and develop Upgrade/Conversion Packages that enhance performance and improve the ease of maintenance of your primary breakdown equipment. No matter what machinery you are running you can always improve the performance.

- Telescoping splined drive shaftsconversions to power your spiked rolls at the log turner, as well as your rolls at:

- The bottom head spiked rolls

- Side head feedrolls

- Top head press rolls

- Edger in-feed and outfeed rolls

- Sharp chain conversions

GET A QUOTE

Dave Carlson

Sawmill Machinery Manager

250-710-1691

Experience & Innovation

We work with the best in the industry

Now that Rockwell Industries has joined Promac Group, the best designers, fabricators and service technicians in the industry now work under one roof. For our customers, this means unparalleled customization and exceptional service. It’s exciting work with such a dynamic team to continue to revolutionize the industry.

Industry leading solutions

When speed and efficiency matter most.

- Our pneumatic tire holds down rolls securing the log firmly without damaging any fiber. In addition, the lightweight rolls allow you to use less air pressure during the lift cycle.

- Our quad spiked rolls carry the log with greater stability across your bottom head, giving you more ‘traction control’ for steady feeding, as well as improved hold back power.

- Our replaceable threaded spikes that are considered the best in the industry

- Our heavy duty telescoping drive shaft powers spiked rolls with the motor and reducer ‘fixed’ to the overhead frame out of harm’s way — it’s the fastest log turner anywhere.

Subscribe for Updates

Sign up to get access to exclusive offers, latest news, and more from The Promac Sawmill Team.