The Situation

Pulp mills require very specialized parts, and can have a hard time getting them fixed when they fail or wear out. This is often because the original manufacturer has gone out of business, and/or the intellectual property rights have been sold so many times that there is no customer support/product knowledge left.

Compounding this problem is the reality that pulp mills don’t generally stock more than one spare part. So if a part stops working, the company’s lead-time suffers.

In this situation, Catalyst Paper did what it has been doing for over 10 years: came to us for a replacement part because they know that’s what we do best. Their 3 mills rely on us to quickly remanufacture parts that fit perfectly and have a longer lifespan.

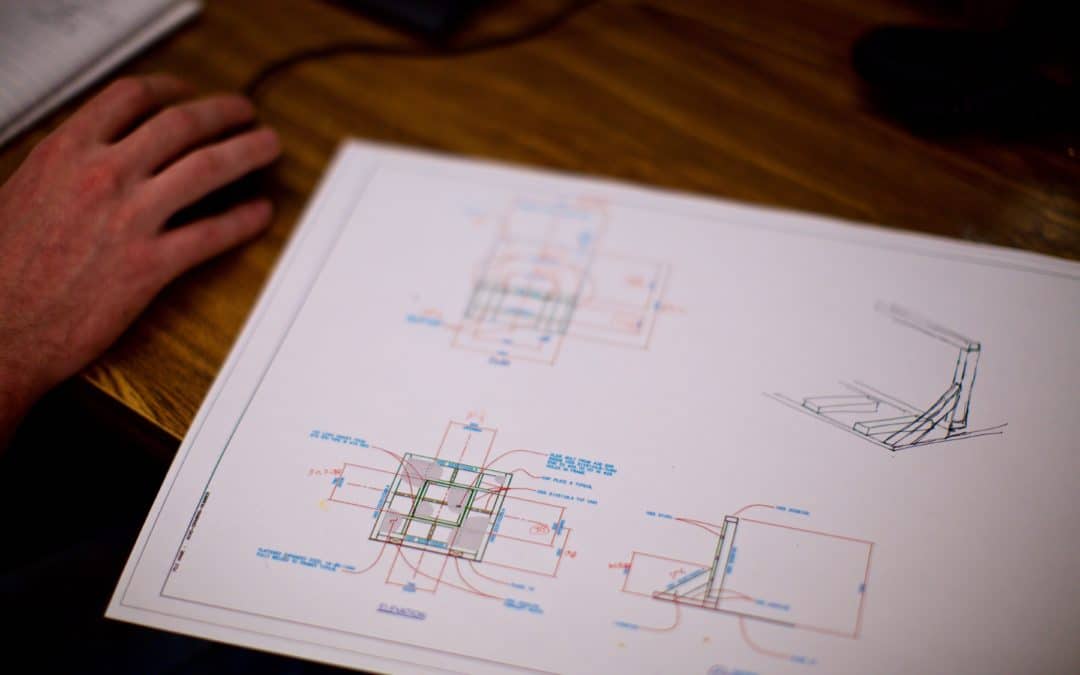

The process

We start off any remanufacture project the same way: we rebuild the part, remachining it back to new. During this reverse engineering process we learn a lot, document everything, and share our intel with the maintenance manager.

Our advantage is that we can see where the design flaws are and where the equipment is wearing out – even in places it shouldn’t. And because everything we do is in-house, our assess-engineer-rebuild-install flow is precise and efficient.

Our solutions often involve ‘small but mighty’ improvements, such as building cleaner knives, hardening the facing of a knife, improving weld overlays and supplying install kits. These changes are grounded in our 45+ years of expertise, and significantly extend the lifespan on the part.

We also look for opportunities to keep costs down, such as by suggesting slight redesigns that will make the part work for multiple mills/operations.

The results

Catalyst cares about lead-time above all else. We get their equipment back up fast, and keep it running longer. That’s what keeps them coming back year after year.

Of course, their second priority is cost. Our accurate quotes are similar to the pricing of the original parts, and we can supply it quicker and it works right away. So that keeps the ‘bean counters’ happy. But what makes them even happier is that our parts are better than original, because we build in intelligent improvements that can extend the lifespan by a factor of years.